Ford is investing $5 billion to change the way it makes electric vehicles, a move the automaker says will allow it to manufacture models starting at $30,000 — far less than the current average price for an EV.

The Dearborn, Michigan-based company on Monday said it will invest $2 billion to modernize its Louisville Assembly Plant and another $3 billion to build a new battery plant in Michigan, part of its push to produce more affordable EVs.

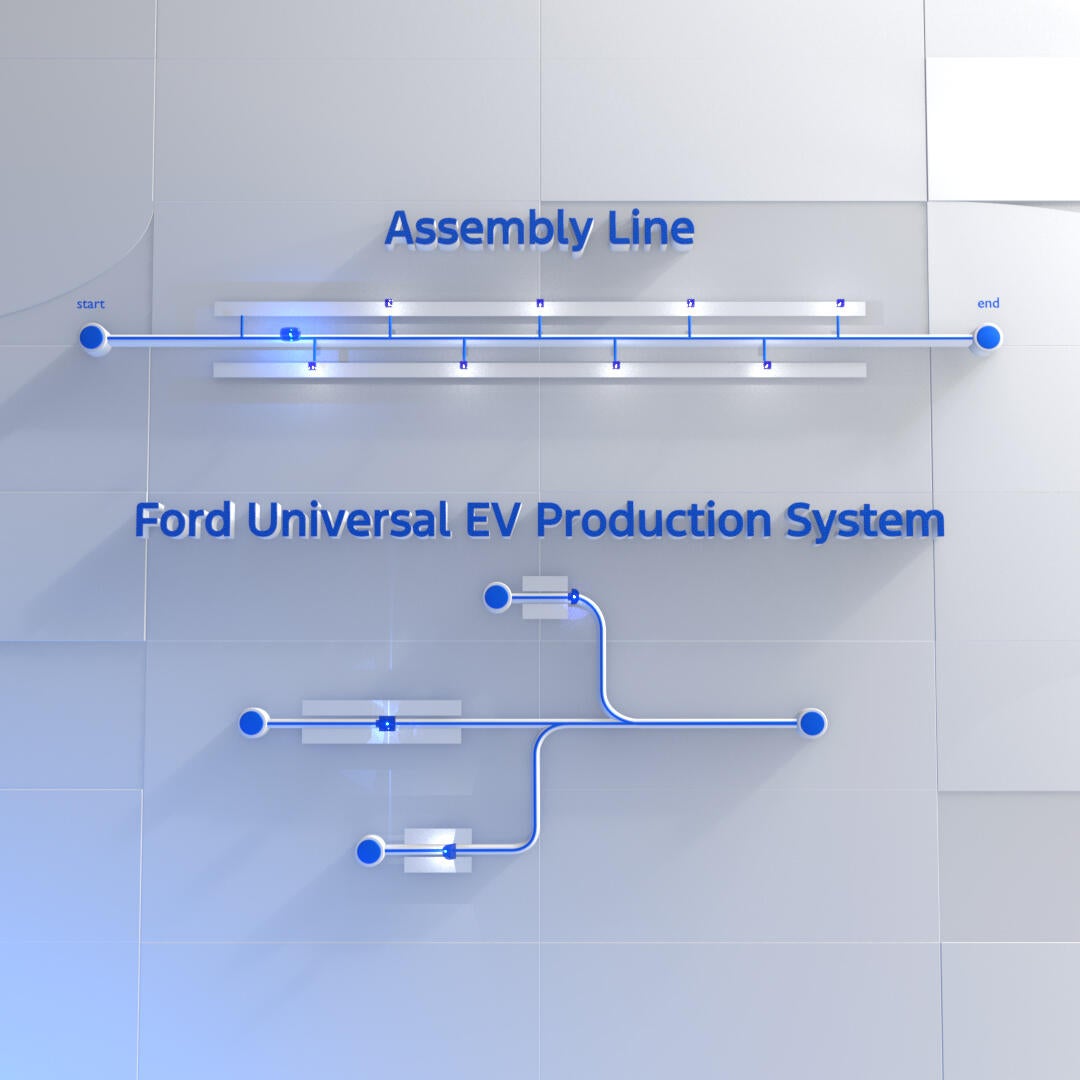

The company unveiled its new “universal EV platform” at a Monday event, with Ford CEO Jim Farley calling it “the most radical change on how we design and how we build vehicles at Ford since the Model T,” which Ford introduced in 1908.

According to Ford, the new assembly line will be structured more like an “assembly tree,” with three different lines that converge into one, rather than a single assembly belt.

Ford Motor Company

“This way of building a vehicle, we’re confident, is the first time anyone’s done this anywhere in the world,” said Doug Field, Ford’s EV chief of digital and design, at Monday’s event.

The company said the design will lead to a quicker, smoother assembly process and improve ergonomics for employees through a less obstructive layout.

“Ford’s announcement is very ambitious, because it includes both a new production process and a new vehicle,” said Patrick Anderson, founder of Michigan-based consulting firm Anderson Economic Group, in an email to CBS MoneyWatch. “If they can actually pull off a production line that has 40% fewer workstations and 20% fewer parts, it will be worthy of the ‘Model T moment’ claim.

Ford’s first EV from the new system

The first product of this new production system will be a four-door midsize truck, which will debut in 2027. Farley said on Monday that the new vehicle will accommodate five people and feature a “frunk” — a front storage compartment — as well as a pickup truck bed.

The vehicle will start at $30,000. By comparison, the average price for a new electric vehicle in July was about $56,000, according to Kelley Blue Book.

Field touted the new vehicle’s charging capabilities, referring to the truck as a “mobile power plant.”

“Outlets in the back can give you high power and let you plug in anything from tools to a refrigerator, and it can provide backup power for your home,” he said.

The midsize electric truck could be produced up to 40% faster than other vehicles at the Louisville Assembly Plant due to the new process, Ford said.

In another effort to lower costs, the auto company is also reducing the number of components that go into each car. Vehicles produced on the “universal EV platform” will have 20% fewer parts than a traditional vehicle, Ford said.

The company will also use smaller cobalt and nickel-free batteries that will allow it to make “cost gains,” according to a video shared by Ford.

Anderson said that Ford has its work cut out for them given that the new truck will need to be competitively priced and economical. According to the auto industry expert, the cost of charging EV trucks currently on the market is often much higher than the price at the pump for gas-powered versions. A report from the Anderson Economic Group shows pickup trucks drivers in New York, California and Michigan face “significantly higher costs” if they rely on an EV.

A successfully lower-cost truck model, however, could spur a new chapter for the company in its manufacturing of EVs.

“If Ford shows the industry it can build and sell a reliable compact EV truck for $30,000, it will sell a lot of them, and open the door to making sedans using the new production process,” Anderson said.

https://www.cbsnews.com/news/ford-electric-vehicles-ev-production-5-billion-investment-30000-model/